Split up into eight chapters and three annexes, the 2016 edition of NFPA 110 is intended to codify the performance —in installation, maintenance, operation and testing— of emergency and standby power systems.

Split up into eight chapters and three annexes, the 2016 edition of NFPA 110 is intended to codify the performance —in installation, maintenance, operation and testing— of emergency and standby power systems.

In this overview, we’ll address what NFPA 110 is, and how emergency power systems are classified throughout the standard. We’ll also discuss how facility managers, installers and design engineers should —and shouldn’t— interpret NFPA 110 when seeking compliance for their emergency power system.

To learn more about the process for achieving compliance, read our no-nonsense guide to NFPA 110. You’ll learn what you need to consider when designing, installing and maintaining your facility’s emergency power system. And you’ll receive advice on how to work with the NFPA, enforcement agencies and your generator manufacturer to achieve compliance.

First, though, we need to address a few key definitions used throughout the standard:

-

Emergency power supply (EPS)

Essentially, the emergency power supply (EPS) is the source of electrical power (i.e., generator) used in your backup power system (3.3.3). It is independent of your primary source of power, ready to kick on in case of power failure. Within the confines of this particular guide, when we refer to an EPS, we are talking about a standby generator.

-

Emergency power supply system (EPSS)

Your emergency power supply system (EPSS) refers to your functioning backup power system in its entirety. It includes the EPS, transfer switches, load terminals and all the equipment required to provide a safe and reliable alternative source of power for your facility (3.3.4).

-

Authority having jurisdiction (AHJ)

Authority having jurisdiction (AHJ) is a broad term referring to the agency or agencies responsible for enforcing code compliance in your particular city or region (3.2.2).

-

Approved

NFPA 110 defines something as approved when it’s “acceptable to the AHJ” (3.2.2). This is important: The NFPA doesn’t approve any equipment or installations as being “compliant” with NFPA 110 (A.3.2.1).

The only way to guarantee your installation, procedures or equipment are compliant is to work with your AHJ to ensure it aligns with all applicable standards, policies and codes, while referencing this standard and your manufacturer’s recommendations.

These terms are at the core of NFPA 110. Essentially, the standard provides requirements and best practices for the setup and ongoing performance of EPSS’s to ensure they are able to provide prompt and reliable power in the event of the failure of your primary power source, minimizing the risk to human life. For a complete guide to compliance, download our straightforward guide to NFPA 110.

The keys to understanding NFPA 110: Level, Class and Type

The key to understanding the requirements outlined in NFPA 110 lies in acquainting yourself with the way emergency power supply systems (EPSS) are classified: By Level, Class and Type.

These categories dictate decisions including (but not limited to) what equipment to use, where to store the system and how much fuel to keep on site as required by your facility’s application, location, proximity to fuel and level of life safety risk.

NFPA 110 Level

There are two EPSS levels defined in the standard: Level 1 and Level 2. They’re distinguished by the types of loads they carry, and have different equipment and installation standards.

Level 1 EPSS systems provide power where failure would result in “loss of human life or serious injuries” (4.4.1). Level 2 EPSS systems carry loads “less critical to human life and safety” (4.4.2). As you can imagine, Level 1 EPSS systems are subject to stricter design guidelines. Most equipment is designed for Level 1 requirements, and can be used for the less strictly regulated Level 2 loads.

It’s important to note that NFPA 110 does not state which applications, specifically, qualify as Level 1 or Level 2 — that is up to the AHJ’s interpretation (1.1.5). They do, however, provide some examples of situations where a Level 1 or 2 EPSS might be required.

- Possible NFPA 110 Level 1 applications

Life safety illumination, public safety communication systems, fire pumps, ventilation equipment (A.4.4.1). - Possible NFPA 110 Level 2 applications

Heating and refrigeration systems, sewage disposal, some industrial processes (A.4.4.2).

NFPA 110 only defines systems with a direct impact on life safety — even the failure of a Level 2 system would have significant ramifications for occupants if it failed (1.1.3). Due to the effect of Level 1 and 2 loads on life safety, NFPA EPSS systems must be permanently installed to ensure it kicks on in case of your primary power source’s failure.

As you’re likely well aware, there are certain non-essential applications (i.e., data centers, research facilities) where failure could result in the loss of millions of dollars. These types of loads would be served by optional standby generators, which aren’t defined in NFPA 110 because they aren’t essential to life safety.

Facility managers looking for compliance guidance for a necessary (but not legally required) unit should turn to NFPA 70, more commonly referred to as the National Electrical Code® (NEC®). Article 702 contains helpful information regarding the design and installation of optional standby power systems.

Actually, there is quite a bit of overlap between the NEC® and NFPA 110. NFPA Level 1 roughly equates to Article 700 for “emergency systems,” and Level 2 to Article 701 for “legally required standby systems.”

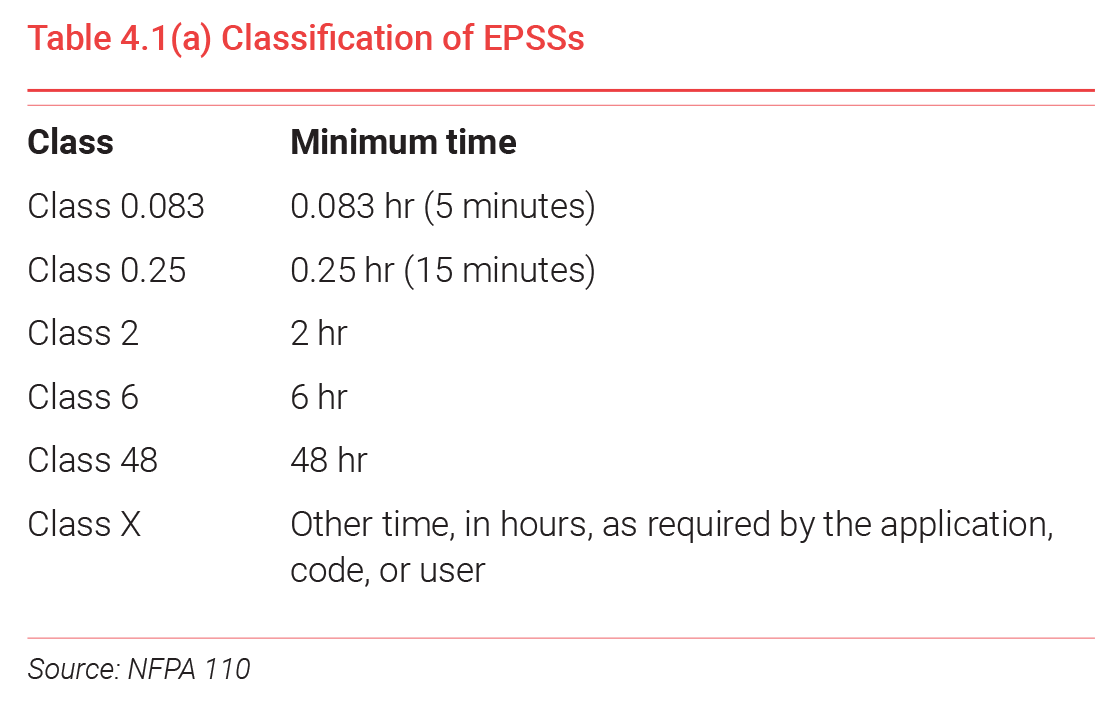

NFPA 110 Class

Your EPSS Class is the duration (in hours) your system must be able to run at its full rated output without refueling (4.2).

Class 2 requires your gen set run for 2 hours without adding fuel, Class 48 requires 48 hours and so on. Although some AHJ’s define “Class X” differently, it generally translates to 96 hours of rated output.

Higher Classes pose a challenge for system designers —especially designers of larger systems— as you must have enough fuel stored on site to satisfy your gen set’s fuel consumption for the duration as defined by your Class. Let’s say you require 18,000 gallons of fuel to run your EPS for 96 hours because you have a Class X EPSS installation. According to the 133% rule, you need to store almost 24,000 gallons on site.

You’ll need to carefully size your fuel tanks and perform regular fuel maintenance to ensure compliance (7.9). You should also consider fuel supplier delivery logistics — if you’re in a rural area where it’s going to take a while to get more fuel if you run out, you might consider oversizing your tank even further.

You should work closely with your gen set manufacturer to come up with a fuel storage and maintenance plan that complies with this standard and all applicable codes, without being cost prohibitive. At CK Power, our compliance specialists will help you size your tanks correctly during design, and maintain your stored fuel throughout the lifetime of your EPSS.

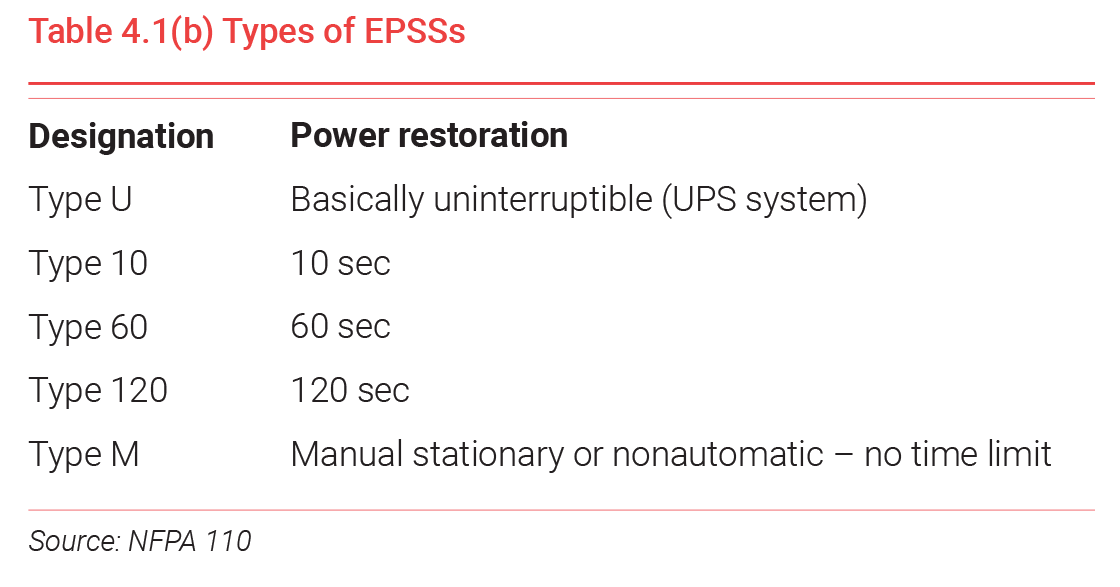

NFPA 110 Type

Type refers to the time (in seconds) your system has to be up, running and carrying your Levels 1 and 2 loads. For emergency power —defined as Level 1 in NFPA 110— 10 seconds is the standard. That means all Level 1 loads need to be transferred to your EPSS in 10 seconds, no matter how large or small your system is.

To prevent nuisance starts, there’s usually a time delay of about 1 to 3 seconds on the transfer, leaving even less time to move the load. With bigger units, the time delay is sometimes reduced to buy more time for the transfer. For instance, a time delay of 3 seconds give 7 seconds for the transfer. Reducing the delay to 1 second gives 2 more seconds to transfer the load, which could be critical for larger applications.

You need your EPSS to kick on within a reasonable timeframe after power failure — and you need it to fulfill your load requirements in full until your primary power source comes back on.

And that’s what NFPA 110’s classification method was designed to do: Ensure your EPSS system will provide a “source of electrical power of required capacity, reliability and quality” for the timeframe your application requires (4.1).

A few important caveats about NFPA 110

While it provides guidance to design engineers, manufacturers and governing agencies, NFPA 110 is not an all-encompassing manual for the design and implementation of emergency power systems.

In fact, NFPA 110 dedicates a whole chapter to listing out referenced publications and standards “considered part of the requirements of [the] document.” These publications might be useful in your continued research regarding compliance for your emergency power systems for your facility:

- NFPA 1 – Fire code

- NFPA 30 – Flammable and combustible liquids code

- NFPA 37 – Standard for the installation and use of stationary combustion engines and gas turbines

- NFPA 54 – National fuel gas code

- NFPA 58 – Liquefied petroleum gas code

- NFPA 70® – National electrical code®

- NFPA 72® – National fire alarm and signaling code

- NFPA 99 (if applicable) – Health care facilities code

- NFPA 780 – Standard for the installation of lighting protection systems

- ASCE / SEI 7 – Minimum design loads for buildings and other structures

To ensure your system is compliant, you’ll need to reference all applicable codes and standards in your area and work closely with all AHJ’s. By familiarizing yourself with the necessary codes —and working with the appropriate state and federal authorities to certify your emergency power system— you can be sure your backup emergency power will kick on when you need it most.

To learn more about how to achieve compliance for your emergency power systems, download our no-nonsense guide to NFPA 110. You’ll learn what you need to know about gaining approval for your emergency power system installation and ongoing maintenance plan. To get a jumpstart on achieving NFPA compliance, download the guide now.