Phenix Technologies, a manufacturer of test systems and components for high-voltage, high-current and high-power applications, asked CK Power to custom engineer a new generator set to replace their old set used to perform integrity tests on utility cables. As a part of their integrity tests, Phenix hooks up their testing equipment to the ends of utility cables and alters the voltage from our generators to conduct a voltage sweep of the cables.

The problem

The company’s old generator, used since the 90s, was worn out. They needed a direct replacement that met their specifications while also meeting Tier 4 emissions standards.

One of the major concerns Phenix Technologies encountered was the space restrictions imposed from their previous generator. The company’s application was still fully functioning except for the old generator. Unfortunately, the fully functioning equipment surrounded the previous generator, creating the space restriction. The application required a certain amount of power to fit into the limited space that housed their previous generator.

Phenix was told by their previous generator’s manufacturer that there wasn’t a similar generator set and it would be impossible to make a new generator set fit into the space while still meeting Tier 4 and power generation requirements. The manufacturer claimed Phenix would have to get entirely new equipment for portions of the application in order to free up enough space for a new Tier 4 engine.

The solution

We reviewed Phenix Technologies’ space dimensions, power requirements and specifications needed for the application and began making determinations on how to tailor a generator set that would solve each of their challenges.

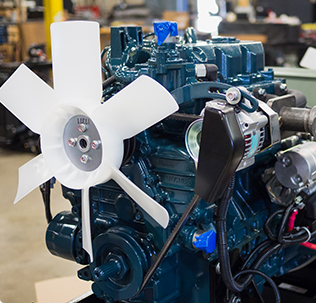

The most unique component of the project was the installation of a second generator. One generator was to be used for primary power while the second would be used to power the controls equipment. By adding a second generator, we had to create a belt pulley system and install an entirely different cooling package. CK Power was the only one willing to create a solution that involved two generator sets powered by one engine set up.

The major challenge we ran into was no one had done a second generator build on a final Tier 4 unit – it was an entirely new solution. Our engineering team had to work with Volvo Penta and the client to figure out how to create the belt pulley system. The biggest concern was that while everything may fit into the space, as the belts loosen over time, would there be enough space and access for their team to perform maintenance to keep the generator running efficiently.

The takeaway

Similar to our work with Tri-Mer, we delivered a custom-engineered solution that the Phenix team could easily install and connect to their application. Additionally, we finished the project in fewer hours than we had estimated. Our engineering staff, along with input from the client and Volvo Penta enabled us to overcome never-before-seen challenges and create a customized solution that met the client’s specifications.

If your existing generator is needing extensive repair and maintenance or should be replaced but space is a key concern, we will work with you to engineer a way to make it happen.

Is your application Tier 4 compliant? Request a consultation and we’ll talk through the solutions to bring your application into compliance.